Services

We offer one-on-one collaboration with companies to improve production processes and conduct feasibility studies. Explore the available infrastructure we offer for testing, validation, and optimisation of your production. Innovation tailored to your needs.

Utilise Our Testing Infrastructure

We at ISyE focus on developing methods, techniques and tools to support production system design and operations. Our activities align with Flanders Make, the Flemish strategic research center for the manufacturing industry.

Our infrastructure includes:

- Digital Twin Control Room

- Smart and Flexible Assembly Lab

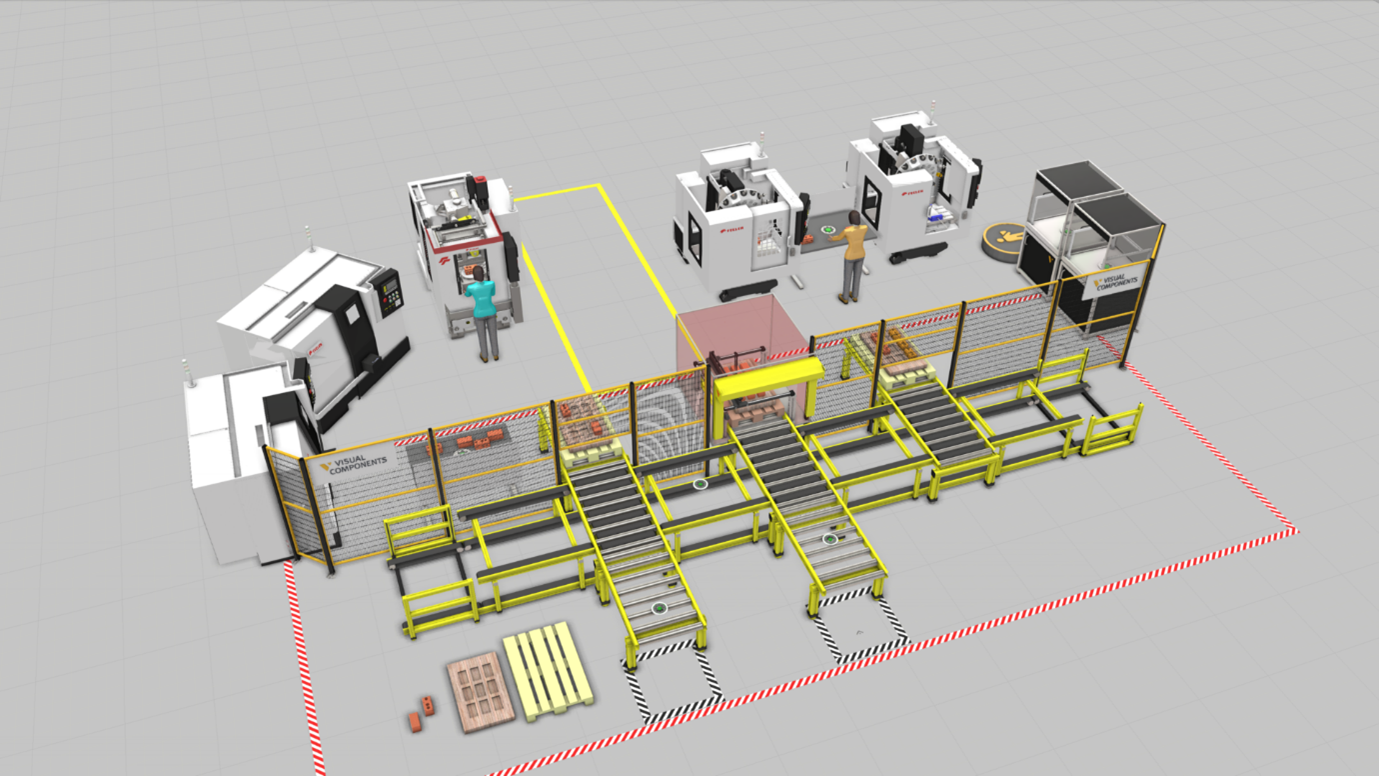

Digital Twin Control Room

Our Digital Twin Control Room is a co-creation space that enables interactive and company-specific production system design, optimisation of production, logicstics and decision-making using digital engineering tools. The control room enables company-specific analysis and validation of industrial workflows, incorporating:

- 180° curved video wall with HD resolution

- 100" multi-touch interactive conference table

- Compatible with most engineering tools such as Visual Components, FlexSim, Siemens PLM

- Data collection platform

- Low-threshold interaction

- Multi-screen sharing (Barco click share & picture-in-picture)

Based on a virtual representation of your production environment or machines different scenarios can be simulated and performances evaluated. The high-performance 3D graphical rendering infrastructure makes for realistic visualisations of the simulated environment.

Our digital tools include:

- FlexSim

- Siemens Plant Simulation

- Siemens Mechatronic Concept Design

- Visual Components

Using these tools, our control room supports:

- Factory layout design and evaluation

- Internal logistics flow design

- Capacity planning and value stream optimization

- Validation of automated system control logic

Smart and Flexible Assembly Lab

Our flexible assembly infrastructure provides testing equipment for demonstrating and validating flexible assembly concepts, including a platform for digital work instructions, work cells with operator support technologies - such as Human Interface Mate (HIM) and Iristick - , collaborative workspaces and operator monitoring systems - such as Smart Floor. Our infrastructure consists of a controlled, realistic 100 m² environment designed for the validation and demonstration of smart and flexible assembly of large, highly variable products.

Specifications

We provide flexible assembly test equipment to evaluate and validate assembly concepts. Through multi-criteria performance analysis, we can:

- Evaluate workstation concepts, including those using mobile and connected resources.

- Assess the impact of various operator support tools in production settings.

- Determine the feasibility of flexible automation concepts for real, complex tasks.

Improvements in Production Processes

The increasing demand for customised products has a significant impact on production processes. We assist companies in designing flexible and cost-effective assembly spaces while ensuring efficiency.

Our support includes:

- Advising on the selection, installation, and application of sensors to optimise production processes.

- Feasibility Studies

We assess the advantages and challenges of implementing innovative technologies in your business. This includes:

- Identifying potential pitfalls in implementation.

- Determining missing knowledge or technologies required for a successful integration.

- Providing customized solutions tailored to your company's needs.

Virtual Validation of Industrial Processes

One of ISyE's key applications of digital twin technology and flexible assemblies is the optimal division of tasks between operators and welding robots through virtual validation of the optimal task sequence and distribution between operators and welding robots based on a simulation model. This results in less waiting time, increased throughput, better transparency in both scheduling and for the operator. This ultimately increases efficiency and convenience for any production company in the metal sector.

Interested in what ISyE can do for you?

Request our tailored services.