Manufacturing knowledge and automation engineering

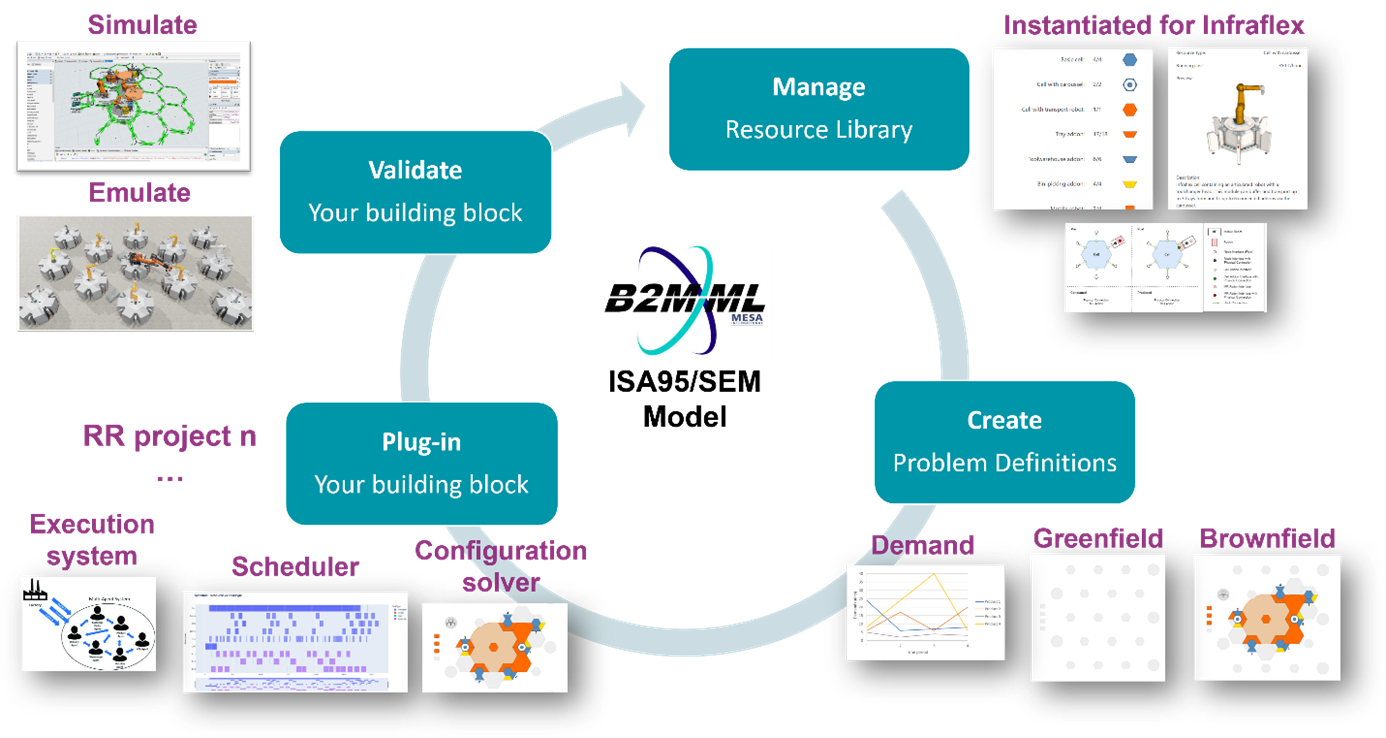

The Manufacturing Knowledge and Automation Engineering domain focuses on advancing manufacturing systems through innovative integration of automation.

Our primary aim is to develop intelligent, efficient, and secure manufacturing processes that adapt seamlessly to human needs and industrial demands. By leveraging standardization and knowledge representation, we develop tools to facilitate all kind of workers in an assembly context by offering personalized cognitive support.

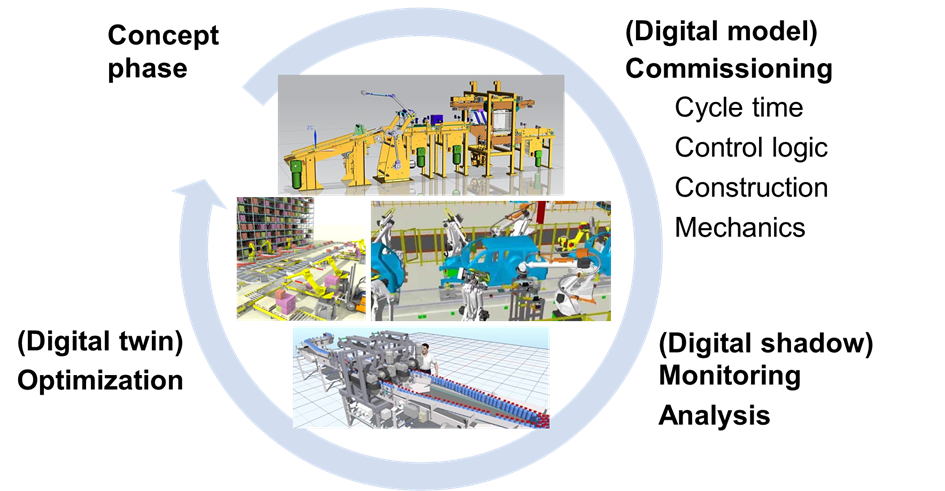

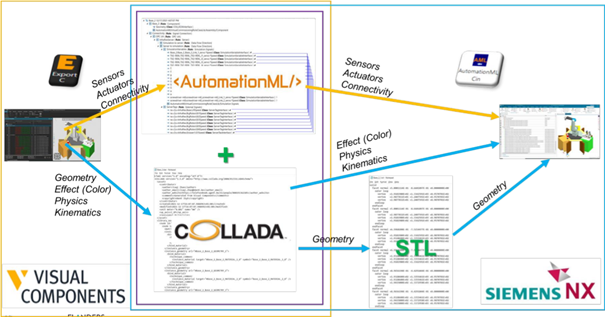

We also specialize in digital twin-enabled technologies, creating virtual replicas of manufacturing systems to optimize performance, speed up the commissioning time and predict maintenance needs, and facilitate real-time decision-making. This approach enhances system transparency and operational efficiency, driving a new era of adaptive manufacturing solutions. Also the interoperability of systems through standardization is a central aspect of our research.

Challenges of Ultra Reliable Low Latency Communication (URLLC) are researched to ensure seamless, real-time information flow across interconnected devices and systems. We primarily target key application domains, including (i) Industry 4.0 for advanced automation on the factory floors, and (ii) Tactile Internet for teleoperation and telemanipulation of remote environments. Within this scope, our scientific activities cover a broad range of communication technologies, including 5G and Beyond 5G, Wi-Fi 6/7, and wired communication systems.