Updated vextool.isye.be platform

(05-11-2025) Our updated platform is live. Discover the latest tools for Virtual Engineering and eXperience, designed to support engineers, researchers and companies in applying digital engineering technologies and moving forward with virtual validation, simulation, and digital prototyping.

What's new on vextool.isye.be?

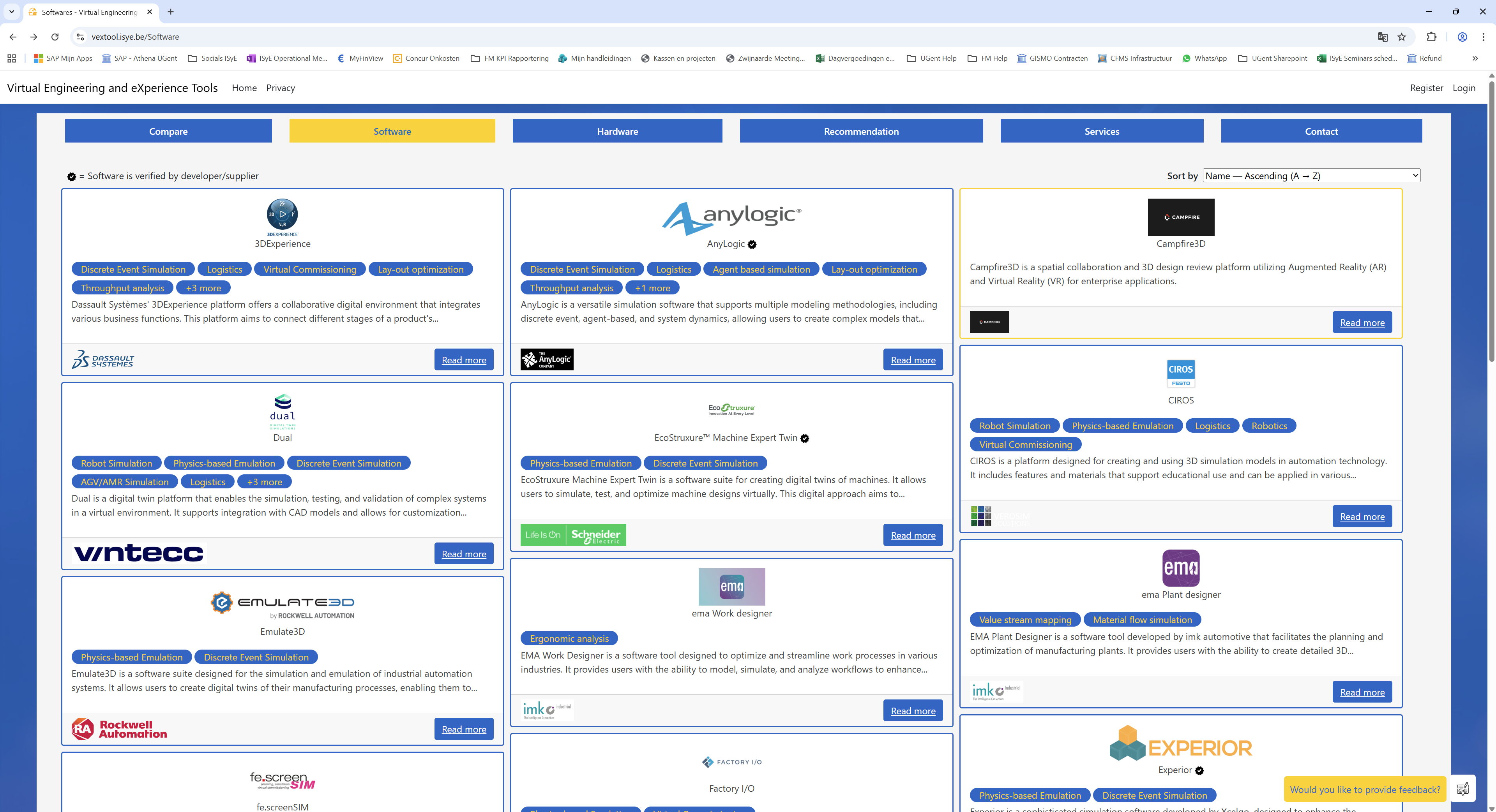

Discover how virtual engineering tools can accelerate your digital design process. Our updated Vextool platform brings together the latest software and methods. Find everything you need in one place: vextool.isye.be.👉 New software added

👉 Improved filtering and search options

👉 Expanded overview of applications and tools

Why vextool.isye.be?

The overall objective is to support system integrators, machine builders, and manufacturing companies in cost-efficiently setting up and maintaining digital twins of production and logistics environments for conducting "virtual engineering" and "virtual experience" projects. Virtually validated is ready for reality.Within VE∞X, Ghent University and Howest are joining forces to demonstrate how virtual engineering and virtual experience can shape the industry of tomorrow. This initiative is led by Prof. Johannes Cottyn and supported by VLAIO.

Using 2D and 3D virtual models helps mitigate risk during the design, implementation, and optimization of production and logistics environments. During this phase, physical environments are often unavailable or unusable due to hardware limitations, production pressure, or complexity.

To support companies in this opportunity, Ghent University is carrying out the VE∞X project together with Howest, supported by VLAIO. The objective is to investigate how companies can make better use of these virtual models. We are looking at two paths. On the one hand, virtual engineering: the path in which virtual models are used to accelerate the design and implementation. A typical example of this is the virtual commissioning of a new installation. The second path is virtual experience: in which extended reality (XR) technology is used to allow industrial users to interact with these new installations very quickly.

The project believes primarily in continuous synergy in both domains, hence the infinity symbol ∞ in between.

Get involved on this topic on LinkedIn.